- Home

- Products

- Food Processing Equipment

- Fresh Food Processing Machine Line

- Vegetable Processing Machine Line

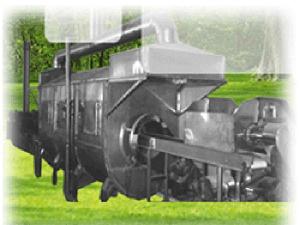

Vegetable Processing Machine Line

The vegetable processing machine line can be widely used in blanching, washing, cooling and water filtration for various kinds of vegetables and fruits before individual quick freezing.

Technical Parameters| Type | |||

| Processing Capacity (Kg/h) | 1000 | 2000 | 3000 |

| Power (Kw) | 11.97 | 14.47 | 19.55 |

| Water Consumption (t/h) | 6.0 | 8.0 | 11.0 |

| Steam Consumption (t/h) | 0.6 | 0.8 | 1.0 |

| Refrigerating Energy Consumption (Kw) | 41 | 48 | 56 |

| Size L × W (m) | 24×1.5 | 28×1.85 | 31×2.1 |

| Weight (t) | 6.5 | 7.5 | 9.5 |

| Processing Time (min) | The processing time can be adjusted within 10~60 mins, and the blanching time can be adjusted within 40 secs ~10 mins. | ||

Features

1. Vegetable processing machine line is made of stainless steel, welded by argon arc welding, which has good sanitation.

2. The processing line adopts automatic conveying system, which is easy to operate. Meanwhile, the speed and temperature can be adjusted.

3. The height of different machining zone is adjustable. At the same time, processes in the line could be combined, added or deleted according to the process or site requirements.

4. The blanching machine adopts steam blanching, so the blanching time can be adjusted continuously. Meanwhile, a steam solenoid valve is installed, which can automatically handle the steam temperature within 90℃ and 110℃.

5. Vegetable processing machine line adopts two times of cooling, and the speed of conveying can be adjusted freely.

6. The processing machine line uses vibration to filter water, so that it can perfectly filter out the residual water on the surface of vegetables and fruits without throwing out the moisture in the raw material.