- Home

- Products

- Food Processing Equipment

- Fresh Food Processing Machine Line

- Frozen Shrimp Processing Machine Line

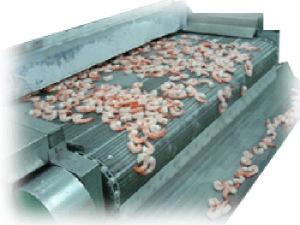

Frozen Shrimp Processing Machine Line

The frozen shrimp processing machine line can be widely used to freeze shrimps of different sizes. The frozen processing machine line consists of the following processes: feeding, boiling - ice cooling - fabric vibration - quick freezing – ice coating - Second freezing.

Technical Parameters| Type | ||||

| Processing Capacity (Kg/h) | 250 | 250 | 500 | 500 |

| Power (Kw) | 18.42 | 26.99 | 25.44 | 27.69 |

| Steam Consumption (t/h) | 0.5 | 0.5 | 0.7 | 0.7 |

| Refrigerating Energy Consumption (Kw) | 90(Without Ice Flume) | 80((Without Ice Flume) | 148 ((Without Ice Flume) | 128((Without Ice Flume) |

| Size L × W (m) | 39.2×1.8 | 31×6.5 | 44.1×1.8 | 34.7×7.2 |

Features

1. Frozen shrimp processing machine line adopts automatic conveying, which is easy to operate, and the speed and temperature can be adjusted.

2. There are two kinds of refrigerants in ice water cooling flume: adding crushed ice artificially and adding cooling fin on the side of the flume.

3. Equipment in each section could be assembled, added or deleted according to process requirements.

4. Equipment in each section is adjustable in height, in order to ensure the smooth connection of each part. According to the customer's field, processing machine line can be arranged in various forms including "-" or "L" .

5. The conveying speed of the whole line can be adjusted according to the processing requirements of the shrimp or shrimp processing technologies; the processing line adopts steam cooking machine, equipped with steam solenoid valve, which can automatically control the steam temperature within 90℃ ~ 110℃.